What is evaporative cooling?

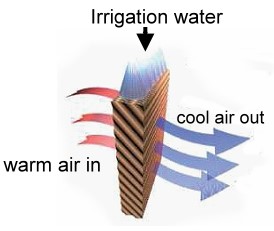

Passing warm air over a wet surface causes water to evaporate and the surface material cools. The surface in turn cools the air passing over it. This in simple terms is what happens inside an evaporative cooler. It is a simple mechanical means of cooling air.

Evaporative coolers have a wetted surface which is normally a 'cross-flow' matrix material that enables water and air to come into contact over a large surface area. This material will have water continuously irrigated onto it by a pump and a fan will ensure that there is an airflow through the material.

What types of evaporative cooling are there?

There are two main types of evaporative cooling system - mobile and installed.

Most people who have come across evaporative cooling before will have come across the mobile type. Whilst mobile evaporative coolers are far more numerous - installed evaporative coolers are far more effective.

There are other types and distinctions - direct, and indirect to mention but two. For now we will keep it simple - mobile and installed.

Why is installed evaporative cooling so effective?

Before understanding why installed evaporative coolers are so effective, we first need to consider why mobile evaporative coolers are limited in their effectiveness.

Mobile evaporative coolers recirculate the air within a room and they don't actually change the air. This means that fresh air has to be introduced from outside by natural ventilation through open doors and windows, or by mechanised ventilation. Air temperatures inside large industrial buildings can get much hotter than outside because the outer fabric of the building will readily pick up radiant heat from the sun and transfer it to the captive air inside the building. Added to that heat can be generated by the processes and machines inside the building. It means that mobile evaporative coolers typically have to cool air from a much higher starting temperature. It is not wonder that they sometimes struggle.

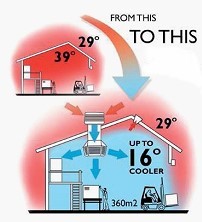

This is how installed evaporative cooling works. Bring in cooler outside air, cool in further, and put it in the building in such as way as it displaces the warm air upwards and out of roof vents.

Installed evaporative cooling is different.

If the temperature of the air inside is 39°C and outside is a fresher 29°C, it is immediately obvious that an installed evaporative cooling system has to do far less cooling than a mobile evaporative cooler in order to achieve the same effect.

With installed evaporative cooling the cooled air is supplied into the building and delivered to the occupied level. The warm air created by the internal processes in the building, and by the buildings' fabric is lifted on this cushion of cooler air and pushed outside through vents in the roof. It means that the warm air does not mix with the cool air and does not impact the working temperature at the occupied level. Contrast this with the mobile evaporative cooler that is in effect mixing the cool air it produces, with the ambient warm air surrounding it.

The installation of evaporative cooling also brings other benefits.

The air, even without further filtration will be cleaner, because it is from outside, and because some of the air-borne dust from outside will be trapped in the water as it comes through the cooler. Because of the addition of ductwork there is also opportunity of fitting in-line heating and ancillary filtration.

Can Heating and Evaporative Cooling be combined?

Yes.

If the evaporative cooling is being fitted to a full distribution duct, then it makes sense to use the same ducting to distribute warm air during the heating season. The heat source can either be 'in-line', such as a heater battery heated by, for example, low pressure hot water, steam, electricity, direct expansion coil, or indirect oil or gas burners.

The other option is to use an end of pipe heat source such as a cabinet heater such as shown so well in the photos below of an installation in Spain.

Combined evaporative cooling and heating installation. Cool air from the evaporative cooler mounted outside, with heat produced by a cabinet heater inside. Balancing dampers can be set to either isolate one machine or the other, or in the heating season the dampers can be set to allow a proportion of fresh air to be introduced by the fan in the evaporative cooler.

Distribution ducting for both heating and cooling air. The air is directed downwards at an angle which is ideal for supplying cool air in summer when warm air is displaced through the roof vents. In winter when the vents are closed to retain heat, the angled inlet grills on the ducting will set a destratifying airflow pattern to recover heat that would otherwise linger under the roof.

A Met Mann AD30 evaporative cooling unit supported on an outrigger framework, supplies fresh cool air in warmer months.

Do you do evaporative cooling installation?

No.

The reason for this is that to offer installation service throughout the UK, we would not be competitive compared to local ducting installers and electricians. We can and do, however, support the local installers in the installation, offering our advice and knowhow, to enable the installation team to achieve the best result. We also offer an on site setting up and commissioning service, which once complete, is the point of validation of the warranty of the supplied equipment.

What range of air flow capacities do your coolers have?

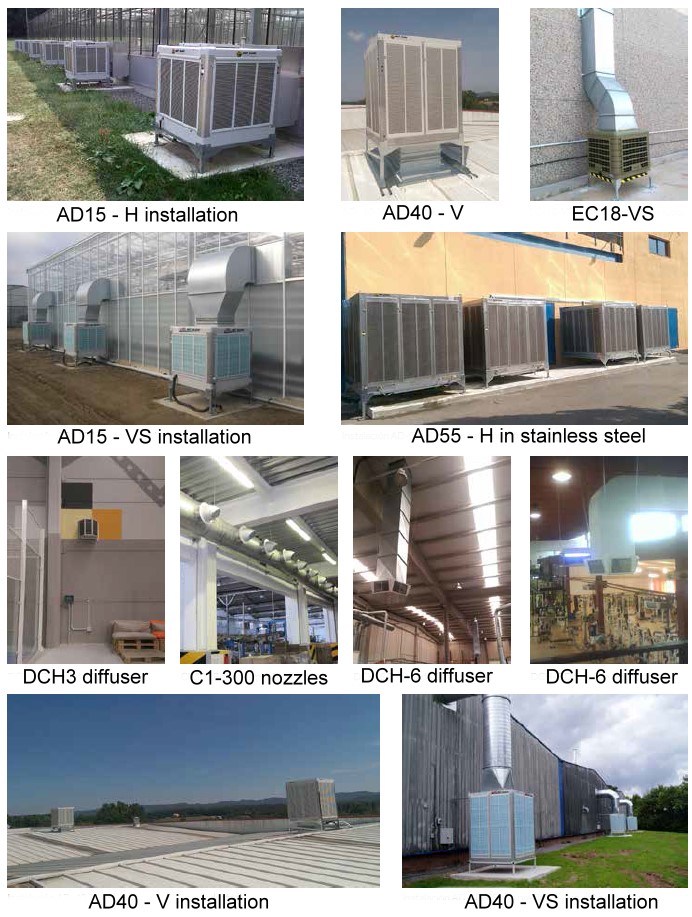

The Met Mann installed evaporative coolers that Puravent supply have 11 sizes rated by airflow capacity from 5500 m3/hr right up to 63000 m3/hr. Each size has 3 variants depending on whether it discharges its cooled air downwards, upwards or to a side.

Is the water quality important?

Yes.

In general terms, the cleaner the water supply, the better. In the UK mains water is perfectly clean enough and typically bore hole water will be clean enough. Water cleanliness is important because mineral deposits can build up on the wetted components in the evaporative cooler. All Met Mann evaporative coolers have a purge system to minimise the build up of mineral crusting, but with higher levels of mineral content there is a limit to how much the purge system can achieve.

Is there any risk of legionella?

No.

The reasons that there is no risk of Legionella in Met Mann evaporative coolers are as follows;

- The water is in continuous movement and is replenished, so stagnation impossible.

- Coolers typically run on potable water which is cool and drinkable and below the temperature above which legionella can proliferate.

- Met Mann evaporative coolers are fitted with an automatic drain valve ensuring the unit empties when not in use and the fan has ‘over run’ function to dry the media panels before the unit switches off completely.

- The water evaporates to gas phase, and the molecules are so much smaller than can support or transport the Legionella bacterium.

- The air speed through the media is typically about 1.5 m/s and always less than <2 m/s therefore airborne droplets cannot be created.

Is installed evaporative cooling cheaper than an air conditioning?

Yes.

However this answer requires some explanation.

Where industrial buildings require cooling to make the working environment inside workable and comfortable, air conditioning is usually not suitable for reasons of scale, practicality and cost. Efficient air conditioning works best where is a high degree of isolation of air within the building so that the same air passes through the evaporator coil, again and again.

Air conditioning is fine for smaller rooms, offices, domestic and small industrial rooms, but when scaled up to warehouse size it becomes prohibitively expensive and can often be impractical because of the air conditionings' requirement for building air tightness. Industrial buildings mostly have frequently opening doors, and free movement of air between different areas within the building.

Installed evaporative cooling obviously costs money to buy and install but importantly it is a very feasible cooling solution for most industrial buildings, complementing the buildings inherent 'openness'. Moreover with very low pressure drop for the fan to overcome and a small pump to circulate the water, the running costs are minimal and a fraction of the cost of running an air conditioning based equivalent system.

Interested to learn more?

- Check out our other guide pages... here

- There is also a cooling blog... here

- Our Evaporative Cooler products are... here

- A short video about installed evaporative cooling... here

- And here are some photos of evaporative cooler installations..